Page 101 - STG Corp 2019

P. 101

MATERIALS

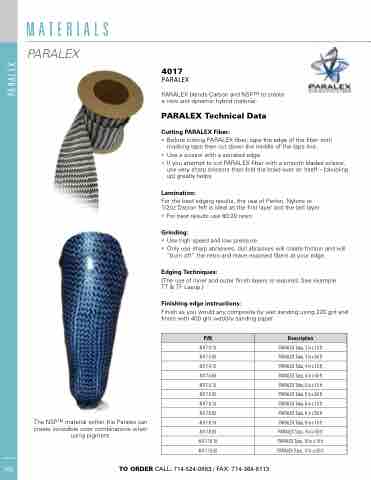

PARALEX

4017

PARALEX

PARALEX blends Carbon and NSPTM to create a new and dynamic hybrid material.

PARALEX Technical Data

Cutting PARALEX Fiber:

• Before cutting PARALEX ber, tape the edge of the ber with masking tape then cut down the middle of the tape line.

• Use a scissor with a serrated edge.

• If you attempt to cut PARALEX ber with a smooth bladed scissor, use very sharp scissors then fold the braid over on itself – (doubling up) greatly helps.

Lamination:

For the best edging results, the use of Perlon, Nylons or 1/2oz Dacron felt is ideal as the rst layer and the last layer.

• For best results use 80:20 resin

Grinding:

• Use high speed and low pressure.

• Only use sharp abrasives, dull abrasives will create friction and will

“burn off” the resin and leave exposed bers at your edge.

Edging Techniques:

(The use of inner and outer nish layers is required. See example TT & TF Layup.)

Finishing edge instructions:

Finish as you would any composite by wet sanding using 220 grit and nish with 400 grit wet/dry sanding paper.

P/N

Description

4017-3.10

PARALEX Tube, 3 in x 10 ft

4017-3.50

PARALEX Tube, 3 in x 50 ft

4017-4.10

PARALEX Tube, 4 in x 10 ft

4017-4.50

PARALEX Tube, 4 in x 50 ft

4017-5.10

PARALEX Tube, 5 in x 10 ft

4017-5.50

PARALEX Tube, 5 in x 50 ft

4017-6.10

PARALEX Tube, 6 in x 10 ft

4017-6.50

PARALEX Tube, 6 in x 50 ft

4017-8.10

PARALEX Tube, 8 in x 10 ft

4017-8.50

PARALEXTube, 8inx50ft

4017-10.10

PARALEX Tube, 10 in x 10 ft

4017-10.50

PARALEXTube, 10inx50ft

The NSPTM material within the Paralex can create incredible color combinations when using pigment.

TO ORDER CALL: 714-524-0663 / FAX: 714-364-8113

106

PARALEX